Analysis

WORKXPLORE comes with a complete set of specialist analysis tools

High performance dynamic sectioning allows users to explore inside a part or an assembly easily and accurately. The dynamic reference controller allows users to control the section plane with the mouse in rotational and panning directions or following a guide curve. The cross section can be made visible on the 3D model or as an isolated entity and can be extracted and exported via the DXF, DWG, etc interfaces.

Generation of the bounding box of a part or a set of parts is instantaneous and provides information on the dimensions, volume and weight of the selected elements and can also be used to determine the optimal stock model required for manufacturing.

Precise measurement information: Information is available both on objects and surfaces and enables rapid calculation of volumes and areas. Complementary information such as the object name, encumbrance, number of faces, etc. is also available.

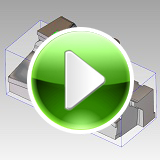

The calculation and display of drafts and undercuts are extremely quick, even on very big parts. WORKXPLORE automatically colors drafts and undercuts according to the mold stripping axis. Precise draft angle values are displayed dynamically as the mouse is dragged over the surfaces and can be inserted by default in the 3D model.

Curvature radius and plane face analysis is a valuable tool for users enabling fast cost and production time evaluation. The coloring of elements to be analyzed is automatic and users can insert measurement labels containing precise values of the elements selected. With WORKXPLORE, the user can view only the concave radii, the convex radii, or both.

A new analysis procedure enables a model's face plane types (planes, cylinders, cones, tores, nurbs) to be analyzed.

The Automatic comparison of 3D models function features a 3D graphic display of the difference between two versions of the same model. The modifications are clearly identifiable by color to distinguish material added from material removed. By clicking on the model, the user can measure the difference in material between the two models.

The projection of a 3D model for creating an object that represents a projected area of an element on one plane.

The analysis of edges and ridges enables sharp and tangent edges of a model to be identified and analyzed.

- Thickness Analysis

The thickness analysis function can be used to highlight critical zones on mechanical parts. Values are indicated on a colour scale which can be represented by colored bands or progressive colour changes. There are three levels of precision to determine analysis rapidity and quality. Users can also obtain information about thickness at a specific point by clicking on the model.

- Improved boundary and edge analysis

It is possible to extract boundary and edge analysis curves. Only the displayed entities are extracted. The result can be saved in the current layer or automatically saved in a new layer. Once the function is active, users can select model edges to obtain detailed information about them. Edge colour varies according to tangency values. Tangency values can also be displayed.