"Surprise, Highly Complex Part" Highlight’s Hexagon's Industry 4.0 Ethos

Access smart manufacturing with Hexagon's software solutions at Global Industrie 2020

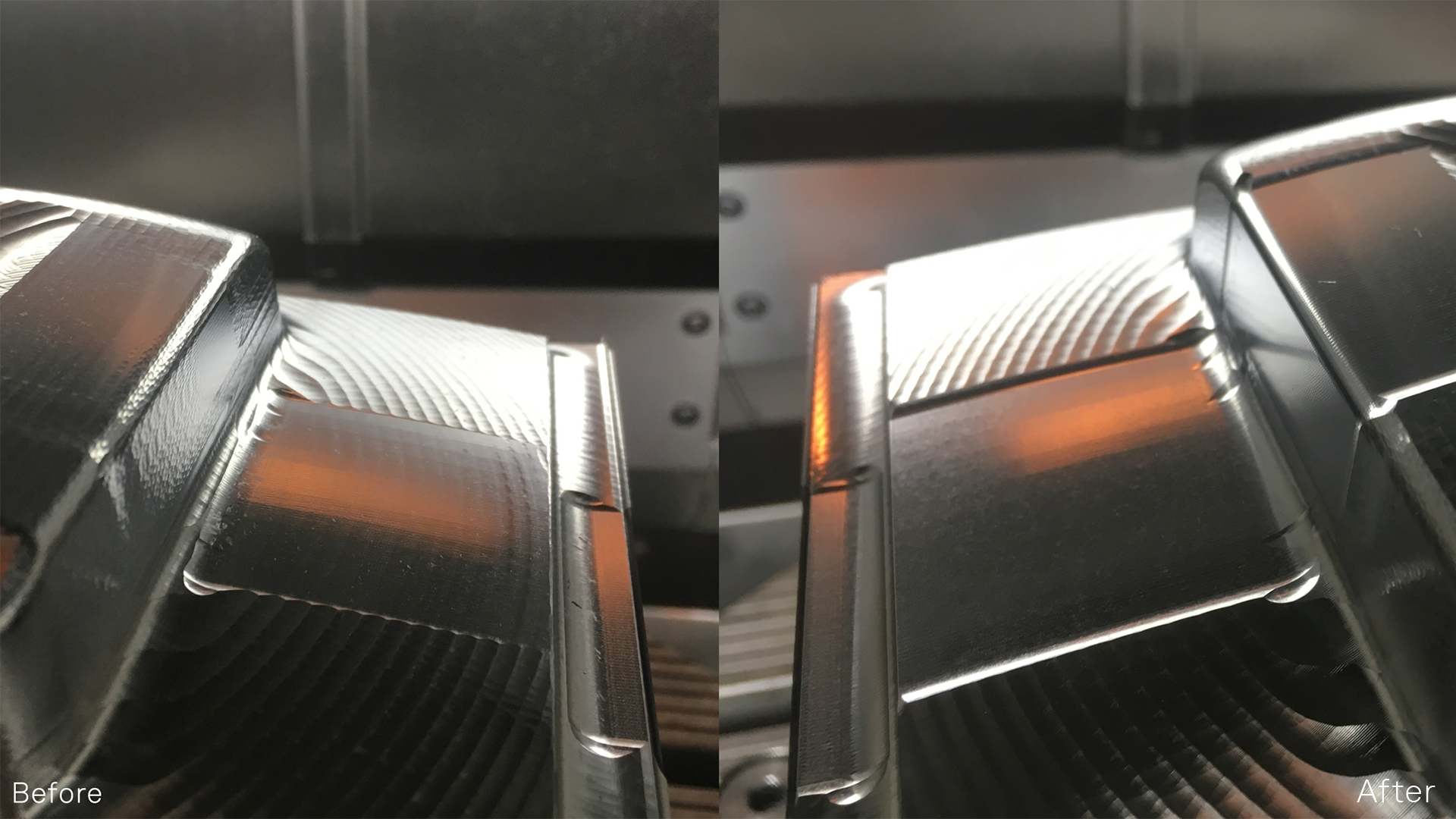

A special, highly complex, machined part will be unveiled at the forthcoming French Global Industrie exhibition, which demonstrates how Hexagon’s solutions combine to meet the needs of Industry 4.0 process optimisation.

The part will be revealed to visitors on the Hexagon stand, P79/87 in Hall 5, soon after the show opens. It was manufactured through a digital continuity process, with Hexagon's CAD/CAM, production management/MES and simulation software solutions.

Visitors will also be able to discover, with the help of Augmented Reality Spectacles, how to quickly deal with interrupted manufacturing issues, thanks to the NCSIMUL 4CAM module. This software automatically converts CAM programs and ISO codes on different machines. It allows automatic and flexible production transfer from one NC machine to another, with NC programs converted in one click, regardless of the type of machine, controller, or kinematics. The setup time for new NC machines is also shortened by using existing NC programs.

The latest versions of EDGECAM, VISI, WORKNC, WORKPLAN and NCSIMUL will be presented at the Global Industrie International Industry Exhibition at Paris Nord Villepinte from March 31 to April 3. These contain new features and improvements which, among other things, drastically improve the efficiency of 5-axis barrel tools and progressive die design, to reduce production times and secure manufacturing.

WORKPLAN and NCSIMUL from the Hexagon production software portfolio are essential to help GE manufacturers, as well as small and medium sized businesses, to make the best possible commitment to the company of tomorrow with intelligent production.

With its new functions, usually found in MES solutions, WORKPLAN becomes the main tool for centralizing a company's data. It improves production management by integrating machine events, monitoring, CMMS (Computerized Maintenance Management System), CAM supervision, workflow and parts traceability. Christophe Mas, brand manager, explains: "WORKPLAN combines commercial and production management, while providing real-time workshop supervision."

NCSIMUL's modules give users complete control over their workshop, including virtualization of real machines, collision avoidance, ISO program verification, toolpath optimization, and program management and transfer. And NCSIMUL Monitor’s machine status monitoring capability improves production.

Two other digital thread processes will also be on display on another Hexagon stand, 5D69 stand in the Measurement and Control sector

NCSIMUL, EDGECAM, VISI, WORKNC, WORKPLAN, WORKXPLORE

Hall 5, Booth P79/87

International Exhibition of Industry in France,

Global Industrie Paris Nord Villepinte, from March 31 to April 3, 2020.